Research Project Outline: Corrosion Resistance of Additive Manufacturing Metals for Renewable Energy Applications

Introduction and Background

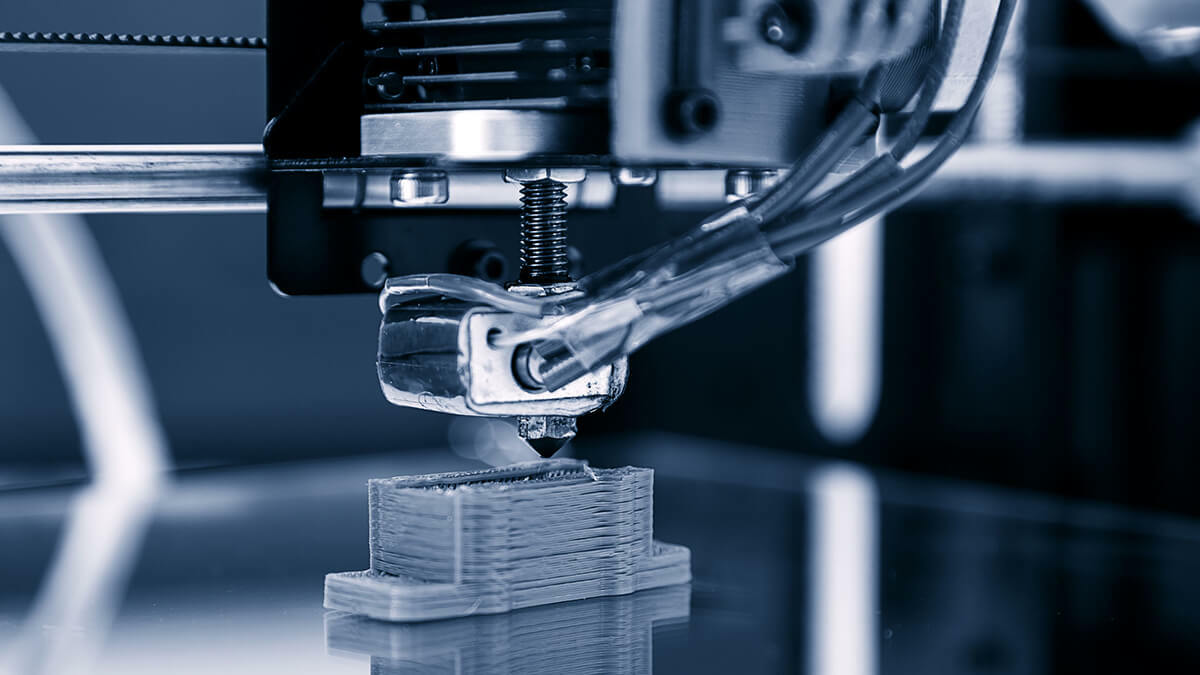

As society transitions towards renewable energy and Net Zero targets, the durability of materials becomes a critical concern. Additive Manufacturing (AM) offers several advantages over conventional manufacturing methods, including bespoke design, material usage efficiencies, and the rapid repair of damaged components. However, the widespread industrial adoption of AM-produced metals is hindered by concerns regarding their corrosion resistance. This project aims to address these challenges by developing a comprehensive methodology for assessing the corrosion resistance of AM-produced metals, thereby facilitating their use in demanding environments such as the energy, automotive, and aerospace sectors.

Research Objectives

The primary objectives of this project are threefold. First, we aim to establish an appropriate test methodology using a flow cell to study the corrosion of AM metals and design experiments that enable the thorough assessment of test materials. Second, we intend to develop a comprehensive database of electrochemical corrosion data and AM build properties, which will be used to establish a framework for machine learning. Finally, we seek to identify key characteristics that can enhance the durability of AM-produced metals, thereby widening their application in various industries.

Methodology

The project will begin with the design of experiments utilising a flow cell to assess AM metals under controlled conditions. Criteria for selecting AM metals and their conventionally manufactured equivalents will be established to facilitate comparative analysis. Electrochemical techniques such as potentiodynamic polarisation and Electrochemical Impedance Spectroscopy (EIS) will be employed to evaluate the corrosion resistance of these metals under controlled conditions, including temperature, pH, and flow rate. Data collected from these experiments will be used to develop a comprehensive database, which will then be integrated with machine learning algorithms to optimise AM processes for corrosion mitigation.

Expected Outcomes

The project aims to develop a robust methodology for assessing the corrosion resistance of AM-produced metals, thereby enhancing their durability and reliability. The database generated through this research will provide valuable insights into the characteristics that improve the durability of AM metals. This, in turn, will facilitate their wider adoption in industries such as energy, automotive, and aerospace, where the demand for durable and reliable materials is high. Ultimately, the project will contribute to material usage efficiencies, bespoke designs, and the rapid repair of components, thereby improving sustainability and reducing material waste.

Research Impact

The anticipated impact of this research is significant. By addressing the current limitations regarding the corrosion resistance of AM-produced metals, the project aims to enhance the adoption and sustainability of AM in various industries. This will support the transition towards renewable energy and Net Zero targets by ensuring that AM-produced metals are reliable and durable in demanding environments. Additionally, the research outcomes will lead to material usage efficiencies and the rapid repair of components, thereby reducing material waste and improving overall sustainability.

Please sign in

If you are a registered user on Laidlaw Scholars Network, please sign in